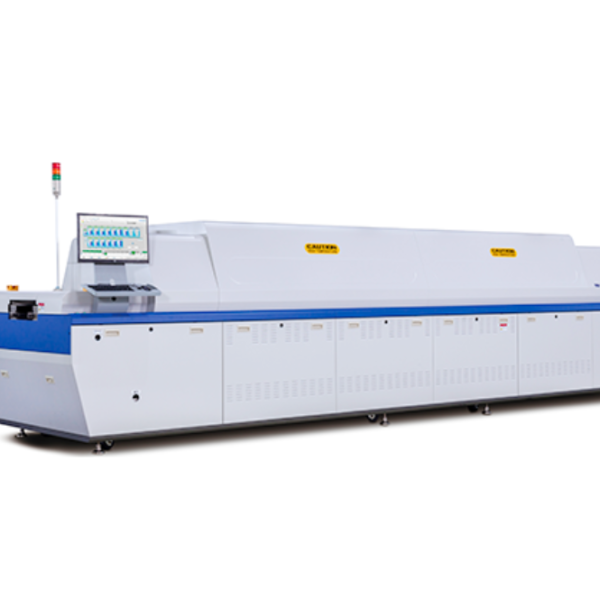

TSM – Vacuum Reflow

The TRV series offers the outstanding productivity and safety operation of equipment. Particularly , the Compact Vacuum Chamber and Conveyor are technically proved solutions in the field through a technical partnership with ETC....

The TRV series offers the outstanding productivity and safety operation of equipment. Particularly , the Compact Vacuum Chamber and Conveyor are technically proved solutions in the field through a technical partnership with ETC.