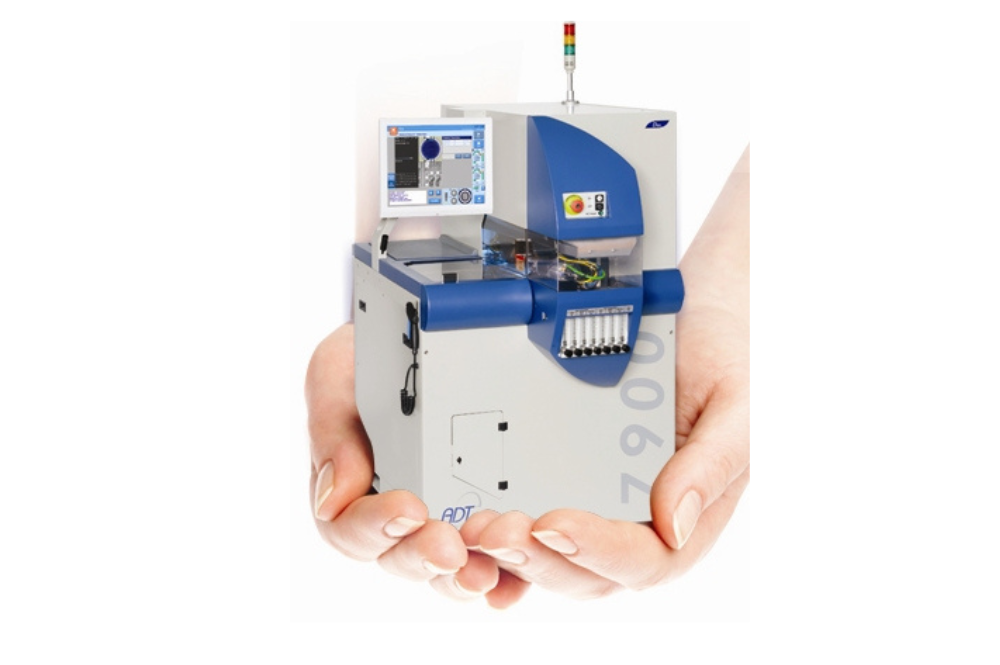

ADT – Dicing Saw

Our ADT dicing saw is a state-of-the-art saw that is fully programmable and controlled by a microprocessor. It is designed for cutting wafer-thin materials into smaller component pieces, with a specific focus on silicon wafers. However, by using the appropriate configuration and blade type, it is capable of cutting any thin material.

The ADT dicing saw is used to cut multi-device substrates into individual chips. The system can accommodate substrates up to 4 mm thick and supports sizes ranging from small pieces to 300 mm diameter wafers.

Key Features

- New User Interface (NUI) Upgrade Kit

- Dicing Floor Management (DFM)

- Height Measurement Tool (HMT)

- Dressing Procedure

Available Models

ADT Dicing Saws

Key Industries

- Semiconductor, Solar & Electronics

More Products

Advanced Dicing Technologies (ADT) specializes in the development and manufacturing of systems, blades and processes used in the dicing of…