ECD – Machine Quality Management

Machine Quality Management (MQM) tools ensure soldering equipment – whether reflow, wave, or selective – is performing to specifications. Keeping a machine operating within its set tolerances sets a good foundation for product quality and high-yield operations. ECD MQM pallets use the M.O.L.E. thermal profiler as the data collection device, enabling the use of one data acquisition system that can be used across soldering equipment platforms.

ECD MQM pallets use the M.O.L.E.® thermal profiler as the data collection device, enabling the use of one data acquisition system that can be used across soldering equipment platforms.

Key Features

- Comprehensive Monitoring: Provides detailed insights into the performance of soldering equipment, ensuring adherence to specified parameters.

- Enhanced Product Quality: By maintaining equipment within optimal operating conditions, the MQM tools contribute to consistent and high-quality production outcomes.

- High-Yield Operations: Ensures that soldering processes are efficient and effective, reducing the likelihood of defects and rework.

- Versatile Data Collection: Utilizes the M.O.L.E. thermal profiler, allowing for a unified data acquisition system across different soldering platforms.

- User-Friendly Interface: Designed for ease of use, facilitating straightforward operation and interpretation of data.

Technical Specifications

Machine Quality Management Series

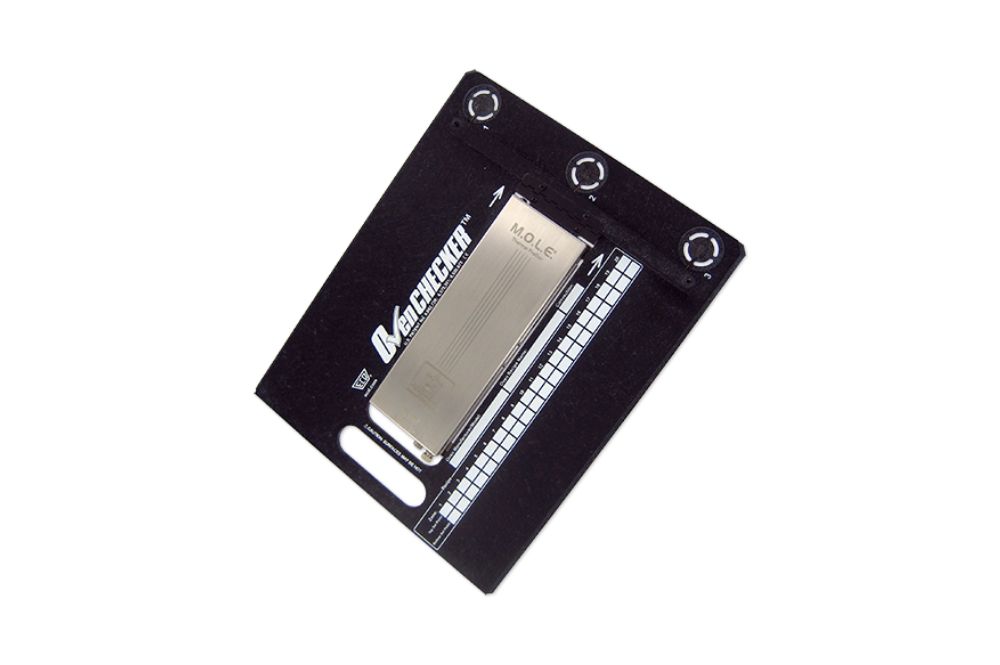

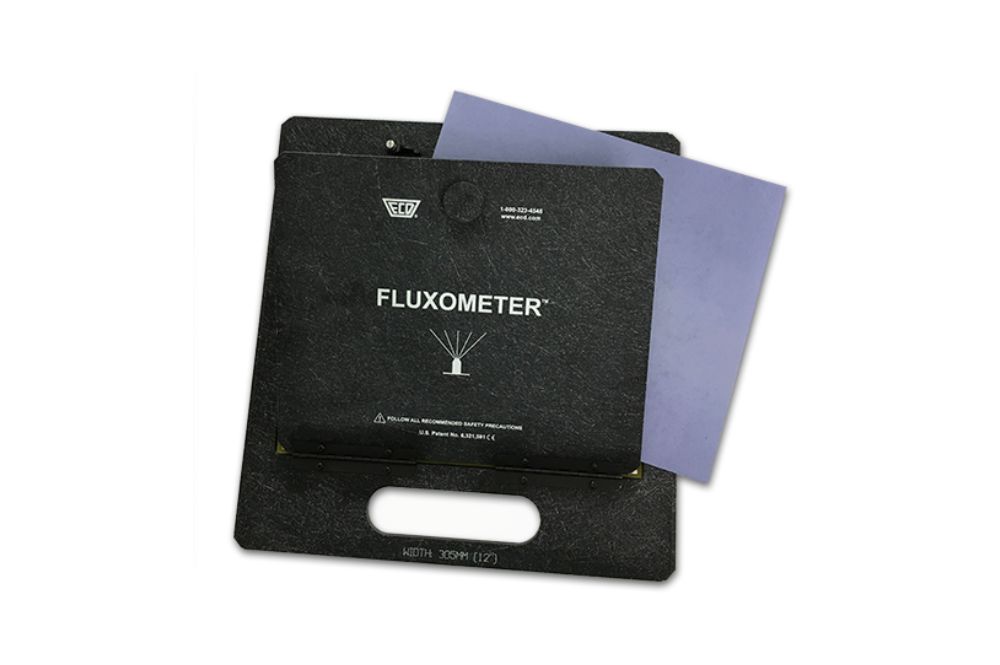

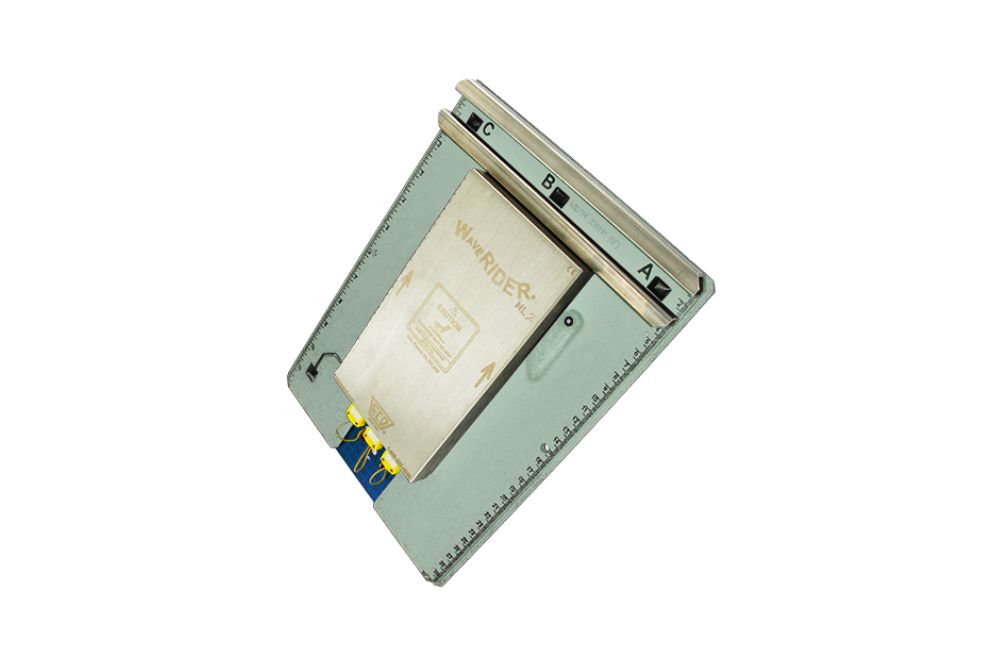

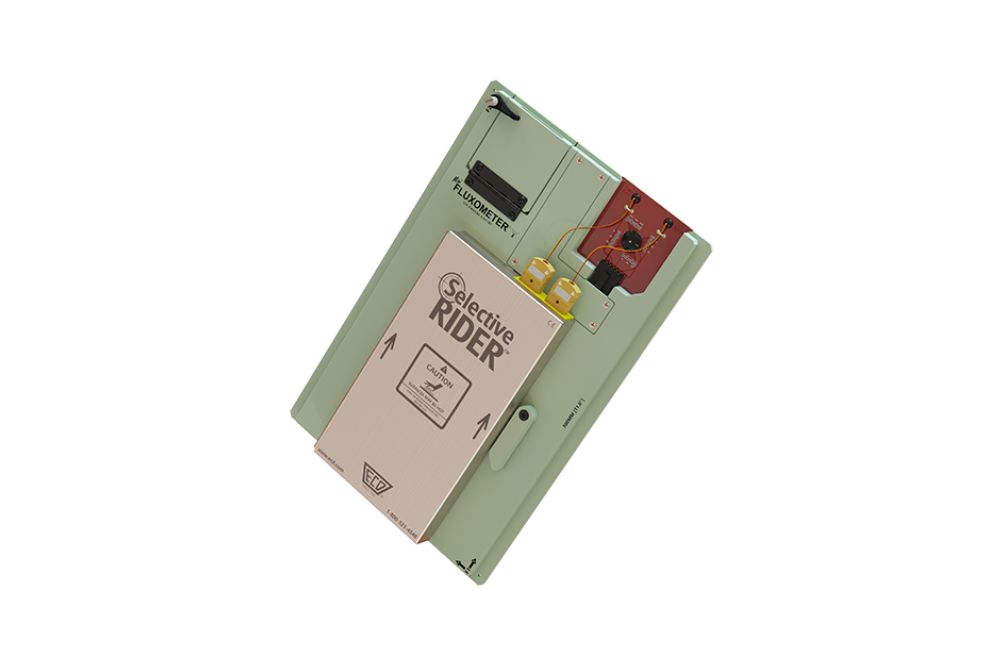

| OvenRIDER™ NL 2+ | SelectiveRIDER™ | WaveRIDER™ NL 2 | Fluxometer™ | OvenCHECKER™ | Reflow Validator™ | ||

| Length | 266.7mm (10.5”) x 241.3mm (9.5”) x 47.6mm (1.88”) | 300 mm [11.8 in.] | 305 mm [12in.] | 313 mm [12.32 in.] | 313 mm [12.32 in.] | 150 mm [5.9 in.] | |

|---|---|---|---|---|---|---|---|

| Height | 31.75 mm [1.25 in] 20.55 mm [0.81in] above conveyor chain | 35.4 mm [1.39 in.] | 33 mm [1.3in.] | 28 mm [1.08 in.] | 2.54cm (1.0in.) 17.8mm (0.7”) above conveyor chain 7.6mm (0.3”) below conveyor chain | 8 mm (0.314 in.) | |

| Width | Standard: 167 mm [6.6 in], 305 mm [12 in], 458 mm [18in] Custom: >167 mm [6.6 in] | 200 mm [7.87 in.] | Standard: 229mm [9”], 305 mm [12”], 381mm [15’], 458 mm [18”] Custom: >145mm [5.7”] | Standard: 229 mm [9”], 305 mm [12”], 381 [15”], 458 mm [18”] Custom: Contact ECD | 30.5cm (12in.) | 250 mm (9.8 in.) | |

| Weight | 6.6”: 1.74 kg [3.84 lb], 12”: 2.81 kg [6.19 lb], 18”: 3.54 kg [7.8 lb] | 1.72 kg [3.78 lbs] | 9”: 1.36 kg [3.0 lbs] 12”: 1.72 kg [3.8 lbs] 15”: 1.86 kg [4.1 lbs] 18”: 2.61 kg [5.75 lbs] | – | 1656 grams (3.65 lbs.) | 200 grams (0.44 Ibs.) | |

| Max. Operational Temperature | 300°C [572°F] | 300°C [572°F] | 300°C [572°F] | – | 300°C [572°F] | 300°C [572°F] | |

| For further details, please refer to enclosed datasheet. | |||||||

Product Gallery

ECD SelectiveRIDER™ Product Launch Webinar

Key Industries

- Semiconductor, Solar & Electronics

More Products

ECD or Electronic Controls Design Inc. is recognized worldwide for its leadership and expertise in thermal monitoring and analysis technology….