Microfluidics International Corporation – Sample preparation – HC Series of Homogenizers

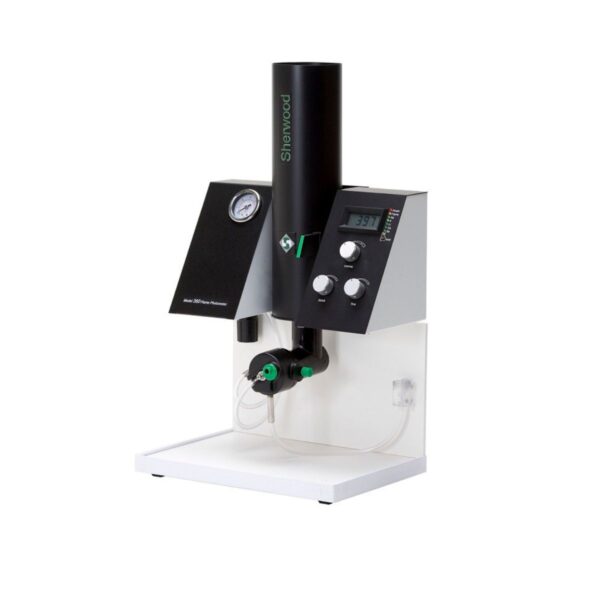

Microfluidizer homogenizers combine superior results with easy handling and small footprint.

The series of air-driven homogenizers are lightweigh and easy-to-use and are suitable for batch and continuous flow processing, often used for emulsions, dispersions and liposomes in pharmaceutical, cosmetic and food and beverage applications. They feature in line cleaning, a pressure gauge, and a small footprint for bench use (or under hood).

The HC pneumatic homogenizers combine high flow with a high-pressure, fixed-geometry Interaction Chamber™ that imparts high shear rates to product formulations. Because every milliliter of your product experiences the same processing, the results include uniform particle and droplet size reduction, deagglomeration and high-yield cell disruption.

Available Models

Key Features

- Unique, wear-resistant homogenizer module — no moving parts

- Pressures to 2,000 psi (HC-2000), 5,000 psi (HC-5000), 8,000 psi (HC-8000)

- Sample sizes of 100 ml (HC-2000/HC-5000) or 250 ml (HC-8000) to continuous processing up to 120 l/hr

- In-line cleaning of high pressure tubing

- Durable plunger seal — offers wide compatibility range and extended seal life

- Air-powered and explosion-proof

- Portable, benchtop

- Process stream temperature maximum of 165°F (75°C)

- Materials of construction for wetted surfaces include: 315 SS, Hastelloy C®, Ky

- Pressure gauge (non-sanitary type)

- Small footprint for bench use, or under hood

Key Industries

- Biopharmaceutical and Biotechnology

- Chemical

- Cosmetics & Personal Care

- Education & Academics

- Food & Beverage

- Medical

- Paper & Wood

- Pharmaceutical

- Polymers, Plastics and Rubbers

- Powders & Pigments / Coating

More Products

Microfluidics International Corporation, the manufacturer of Microfluidizer® high shear fluid processors, is a leader in the design and production of…