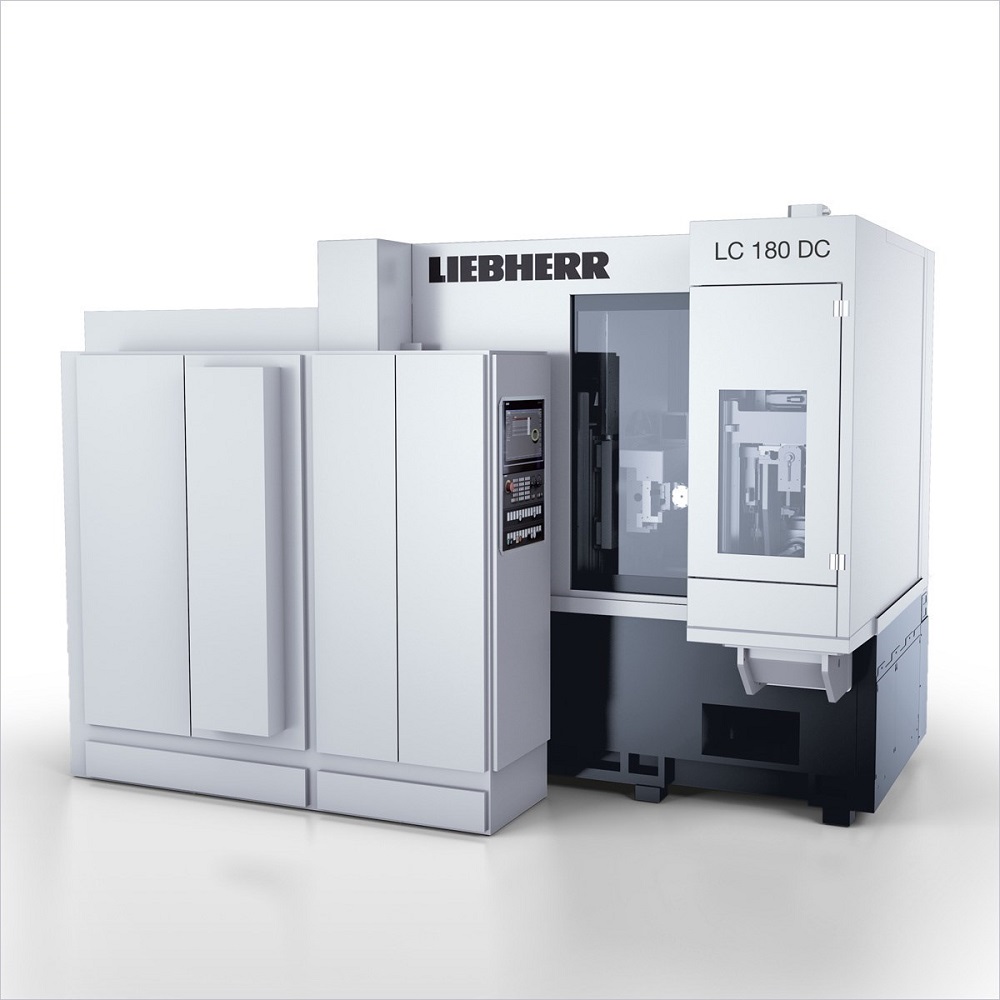

Liebherr – Gear Hobbing – LC Series

Is performance-related cutting possible on your machine? As nowadays the economical requirement is more important than ever, modern machines are required.

The Liebherr series LC ensures reliable processing of the required torques and cutting forces. The capability of modern CNC-Gear hobbing machines is emphasized herewith. Quality requirements such as accuracy, stability and temperature resistance are fulfilled with this machine concept. Stable processes are realized during pre- and finish hobbing.

Key Features

- The compact concept requires 20% less floor space. The proven advantages of the integral loader and part storage system are also available with this machine.

- Significantly increased axis and spindle speeds improve productivity and permit more complex machining processes such as roughing, finishing and chamfering with distinct tools in one setup.

- The tool spindle speed maximum of 7000 RPM allows cutting speeds up to 1700 m/min.

- Table speeds up to 1400 RPM enable the use of high number multi-start hobs to reduce cutting time.

- The workpiece loading time of the highspeed swivel loader for wheels up to 60 mm has been reduced to 1.4 seconds, resulting in a chip-to-chip time of less than 3 seconds. The more flexible ringloader enables a chip-to-chip time of 4.4 seconds.

Available Models

Key Industries

- Machinery & Manufacturing

Brand

Liebherr-Verzahntechnik GmbH, founded in 1969, is one of the leading manufacturers of machine tools and automation systems. The company offers an extensive product program of machine tools and machine automation systems for economic manufacture of gearing products. The company supplies gearings, gearboxes, and slewing bearings to leading worldwide manufacturers.