Essemtec – Dispensing

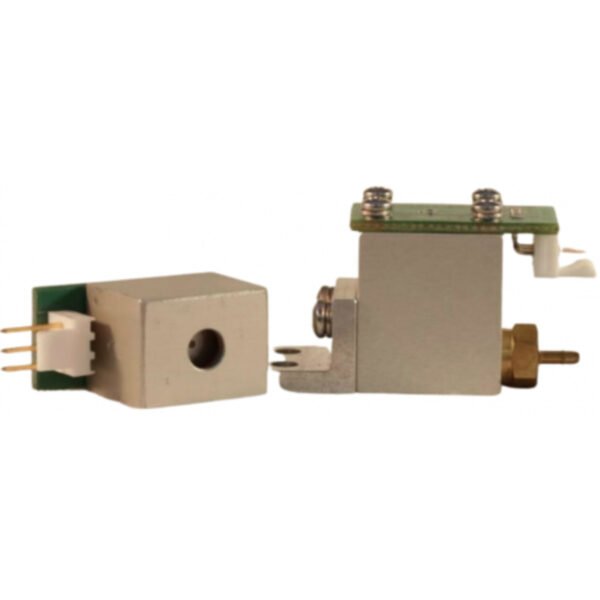

Equipped with the most modern, accurate systems that drive and steering technology offers today. Mediums rarely behave the same way, environmental conditions are significant for the behavior of liquid changes. This is why there is virtually no standard application in dispensing.

Specific solutions for each dispensing task depending on both environmental influences and the type of liquid have to be evaluated. Easy programming and operation allow for a wide range of dispensing applications.

Available Models

Key Features

Essemtec – SpiderCompact Highspeed Jetter and Dispenser 2023

Essemtec Spider, the extreme fast and compact jet and general dispenser is rated for up to 150’000 dots per hour, dispenses 3D patterns and much more.

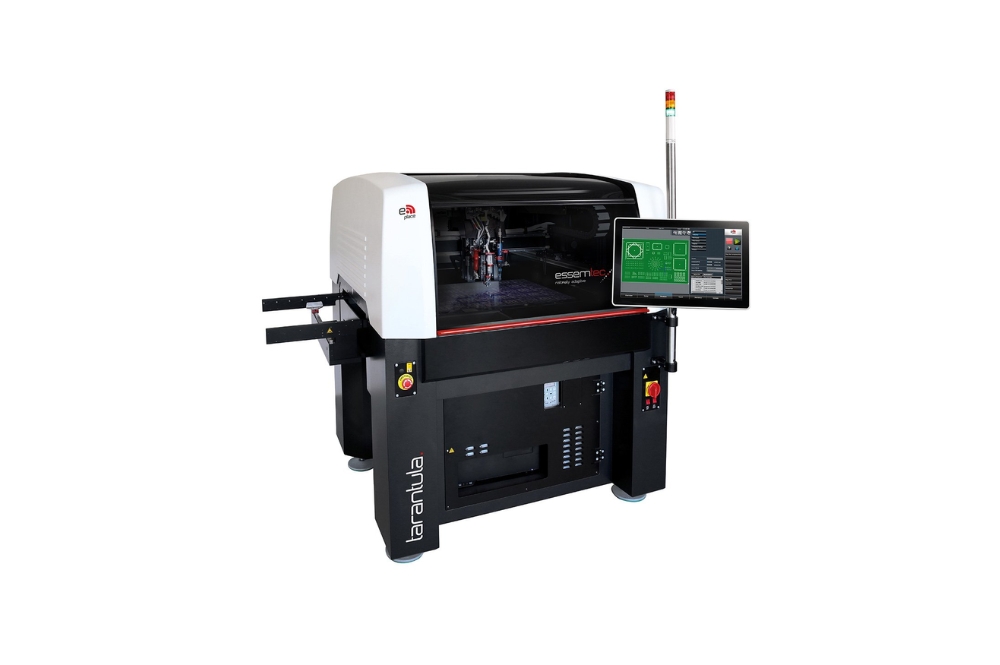

Essemtec – Tarantula

Relentless All Terrain High Speed Dispensing

Introducing – The Tarantula – State of the art technology, easily integrated in any line. Wide range of dispensing applications such as Solder Paste and SMT Glue, LED Encapsulation, Silver Epoxy, Dam and Fill, Underfill, Cavity Fill, 3D Dispensing via laser height mapping and more.

Key Industries

- Semiconductor, Solar & Electronics

More Products

Essemtec leads the industry in adaptive SMT pick-and-place equipment for both high-speed- and micro-dispensing, as well as an intelligent production…