Armfield – Process Control Technology – PCT 50 Series Essentials of Process Control

The Essentials of Process Control (EPC) range of products takes students through the fundamentals of principles of process control, and progresses to give them a thorough grounding in the control of physical processes. Four independent process units demonstrate level, flow, temperature and pressure as the controlled variable. The concepts of closed loop control, including on/off control, proportional control, proportional/integral and proportional/integral/derivative (PID) control can be explored and demonstrated. Some units also cover both time proportioning and analogue control of the same parameter. To demonstrate industrial control systems, two further controlling devices are available, a full function industrial PID controller with autotune, and a programmable logic controller (PLC).

Available Models

PCT50 is a highly visible and easy to understand water level control process. It comprises two clear acrylic tanks; a process tank mounted above a sump tank. Water is pumped up to the process tank and drains back to the sump tank via two valves, one manually variable and the other switched by software. Each valve can also be fitted with different-sized external orifices to change their characteristics. This flexible arrangement allows a wide range of control scenarios to be set up, including two fundamentally different processes, ie:

Level control by proportionally varying pump speed (Inflow control)

Level control by time-proportioned opening of a solenoid valve (Outflow control)

When using inflow control, repeatable disturbances can be implemented using the solenoid valve, and varied by using different orifice sizes. When using outflow control the pump speed can be stepped to provide a full range of repeatable disturbances. These techniques allow direct comparison of different controller settings.

Key Features

- 4.25l process tank, with overflow, mounted above an 8l sump tank

- Level sensor range 0-150mm H2O

- Two discharge ports, one with remote controlled solenoid valve and one with manually controlled valve

- Four interchangeable orifices for use with the discharge valves

- Variable-speed submersible centrifugal pump

- Capable of both analogue PID control using the pump and time-proportioning PID control using the solenoid valve

- USB interface to PC, plus connection terminals for interfacing to external controllers

- Supplied with educational software for PID control as well as data logging

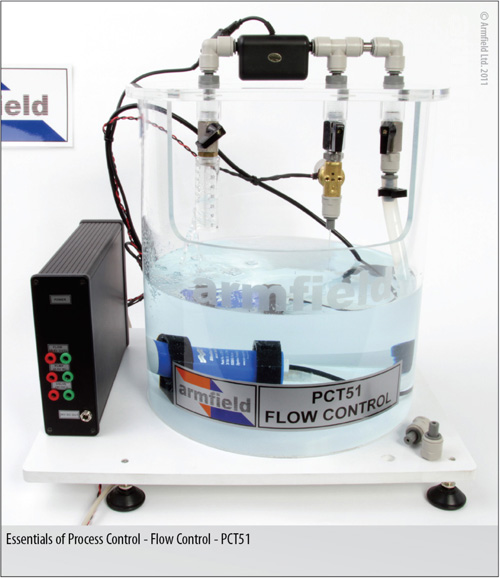

PCT51 is a visible and easy to understand water flow control process. Water stored in the sump tank is pumped through a parallel pipe arrangement mounted on the lid of the tank and returns to the tank via two outlets, a software switched divert valve prior to the flowmeter and a manually operated variable valve after the flowmeter. Both outlets also incorporate interchangeable orifices to vary their characteristics.

The PCT51 demonstrates flow control by varying pump speed. Repeatable disturbances can be implemented using the solenoid valve and a wide range of different control investigations can be implemented using the interchangeable orifices and adjustable valves.

The PCT51 is an ideal system for demonstrating the onset of instability, the importance of filtering on the sensor output, and the trade-off between filter weighting and proportional gain on stability.

Key Features

- 0-4 l/min flow meter, mounted above an 8l sump tank

- Two discharge ports, one with remote controlled solenoid valve and one with manually controlled valve

- Four interchangeable orifices for use with the discharge valves

- Variable-speed submersible centrifugal pump

- USB interface to PC, plus connection terminals for interfacing to external controllers

- Supplied with educational software for PID control as well as data logging

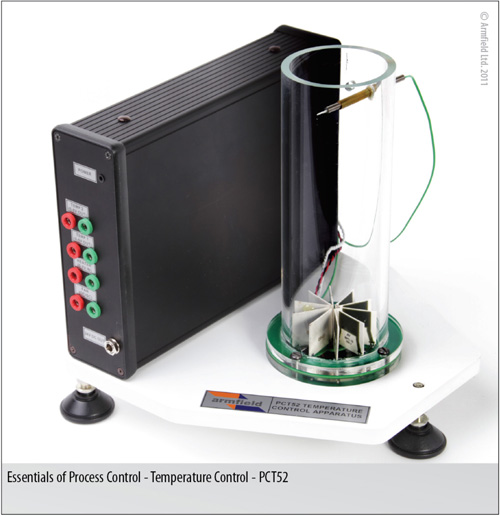

PCT52 is a a visible and easy to understand temp-erature control process. A fan blows air over a heater with radial fins and through a vertical clear acrylic duct. Sensors measure the surface temperature of the heater and the air temperature in the duct. This allows two different control implementations to be demonstrated with very different parameters, ie:

- Temperature control of the heater surface (direct heating)

- Temperature control of the air (indirect heating)

In each case the temperature is controlled by varying the heater power and repeatable disturbances implemented by switching the fan speed, hence allowing direct comparison of different controller settings.

Key Features

- 50W nominal heater mounted in a 60mm diameter duct

- Remotely switchable two-speed fan blowing air over the heater

- Two platinum resistance temperature sensors, 0-150°C range, one measuring the heater surface temperature and one measuring the air temperature

- Capable of demonstrating control of both the heater surface or the air temperature

- Capable of demonstrating the difference between fast-reacting and slow-reacting sensors

- USB interface to PC, plus connection terminals for interfacing to external controllers

- Supplied with educational software for PID control as well as data logging

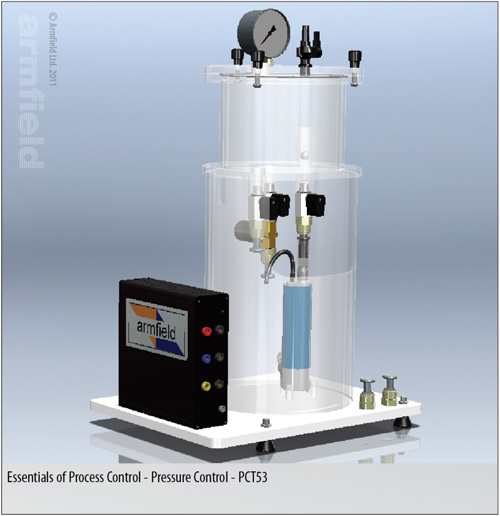

PCT53 is a highly visible and easy to understand pressure control process, which uses pumped water to generate air pressure in a closed tank. It comprises two clear acrylic vessels, an upper process vessel mounted above an open sump tank.

The process vessel is sealed and so the air inside the tank is pressurised as water from the sump tank is pumped into it. Water drains from the process tank back into the lower sump tank via two outlets, one continuous and one incorporating a remotely controlled solenoid valve. Both outlets incorporate interchangeable orifices plus a hand operated variable valve, allowing the flow of water to be varied continuously to suit particular demonstrations.

This flexible arrangement allows a wide range of control scenarios to be set up, including two fundamentally different processes, ie:

- Pressure control by proportionally varying pump speed (inflow control)

- Pressure control by time-proportioned opening of a solenoid valve (outflow control)

When using inflow control, repeatable disturbances can be implemented using the solenoid valve, and varied by using the different orifice sizes.

When using outflow control the pump speed can be stepped to provide a full range of repeatable disturbances. These techniques allow direct comparison of different controller settings.

Key Features

- 2l process tank, mounted above a 3.5l sump tank

- 0-1 bar pressure range

- Two discharge ports, one with remote controlled solenoid valve and one with manually controlled valve

- Four interchangeable orifices for use with the discharge valves

- Variable-speed submersible centrifugal pump used to pressurise the air by water pressure

- Capable of both analogue PID control using the pump and time-proportioning PID control using the solenoid valve

- USB interface to PC, plus connection terminals for interfacing to external controllers

- Supplied with educational software for PID control as well as data logging.

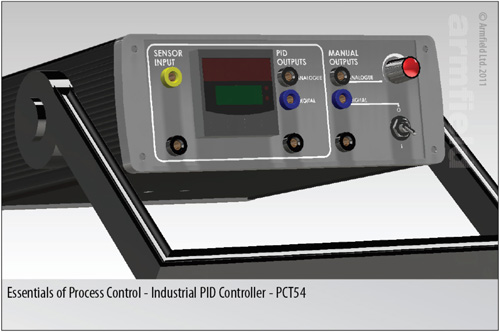

PCT 54 is an industrial PID controller incorporated in a console with input and output connections and controls on the front panel, designed primarily for use with the Armfield EPC series of process control products but suitable for use as a general purpose PID controller. It is supplied preconfigured for proportional analogue PID control, but can be reconfigured to give time-proportioned control using a digital output. The user has full access to the configuration of the controller menus via the buttons on the front or using a USB connection to a PC.

An additional analog output and digital switch allow an uncontrolled device on the process, such as a water pump or solenoid valve, to be operated remotely allowing disturbances to be applied to the process.

Key Features

- Includes manual controls to apply step changes to the process loops

- Can be set up by computer, using a USB interface

- Autotune capability

- Analogue or time-proportioning digital outputs

- Connects to the process under evaluation using simple plug connections:

- One analogue input, 0-5V (from sensor)

- Two analogue outputs, 0-5V, (one from controller, one from manual control)

- Two digital outputs (one from controller, one from manual switch)

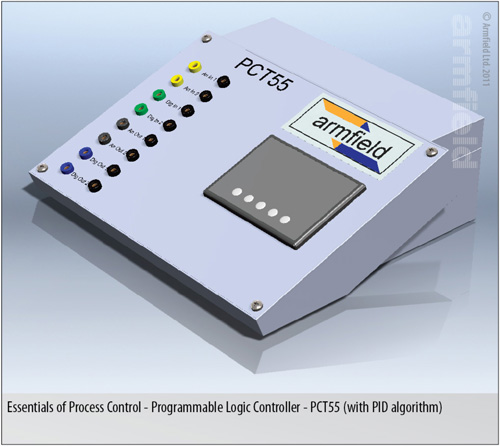

PCT 55 is a programmable logic controller (PLC) with graphical touch screen control panel designed primarily for use with the Armfield EPC series of process control products, but can also be used to control other items. It is supplied with PID control algorithms implemented in ladder logic ladder logic and configured to suit each of the EPC processes.

The user has full access to all the software and algorithms with the following features:

- Calibration of the sensors associated with each product, calibration values can be stored in the PLC

- Specific control exercises written for the four Armfield process units

- Both proportional analogue and time-proportioning discrete outputs

- Individual control of P, I & D parameters, reverting to default parameters for each product on startup

- User selection of sample time, cycle time, filter weighting

- The control algorithms are written as separate sub-routines, making it straightforward for advanced users to write and use their own ladder logic control algorithms

- Control facilities exist for a user-defined process as well as the four Armfield process rigs without having to change the programming

- Freely available programming software for the PLC and touchscreen downloadable from the manufacturer’s website.

Key Features

- Supplied preprogrammed with specific control exercises for the four Armfield EPC processes

- Proportional analogue and time-proportioning discrete PID outputs

- Freely accessible programming software from PLC manufacturer for both PLC and touchscreen

- USB interface to PC for monitoring and programming

- Users can access and modify the ladder logic control algorithms

- Connects to the process under evaluation using simple plug connections:

- Two analogue inputs, 0-5V (from sensors), one analogue output and one digital output

- Additional terminals implemented on the front panel for user programming:

- One analogue output, one digital output and two digital inputs

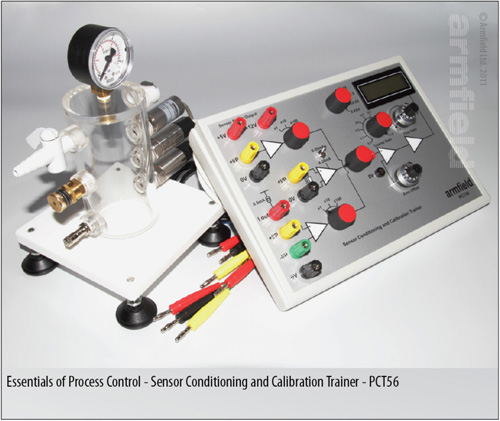

PCT56 is a trainer designed to introduce the essentials of signal conditioning applicable to process measurement sensors. It comprises an electronic console with inputs for sensors with three different types of electrical output, voltage current and resistance. The resistance input can be configured as two-terminal or a four-terminal bridge drive.

Controls on the console allow for ranging, fine scaling and offsetting of the measured values, the output being displayed on a 3.5-digit LCD display. Terminals allow the voltages to be monitored at each stage (voltmeter required). Thus many different sensors with different electrical outputs can be investigated and calibrated on this equipment.

For training purposes, the PCT56 is supplied with three pressure sensors of the same range, but different electrical outputs, plus a simple pressure vessel which can be pressurized using a hand pump.

The pressure vessel also incorporates a fitting for a reference instrument, such as the Armfield H12-8 digital pressure meter. The calibration vessel is fitted with a direct reading Bourdon gauge to give continuous indication of pressure inside the vessel for safety purposes.

Key Features

- Voltage input ranges from 0-50mV to 0-5V

- Current inputs, 0-20mA, 4-20mA

- Scalable resistance and bridge circuit input

- Gain and offset adjustment controls

- Supplied with three 0-1 bar pressure sensors, one voltage output, one current output and one resistance output

- Includes pressure vessel and hand air pump to generate test pressures for the sensors

Key Features

PCT 50 Series Essentials of Process Control

- Open-loop and closed-loop processes

- On/off control (fixed dead band)

- P, PI and PID control

- Underdamping and overdamping

- Time-proportioning control

- Onset of instability

- Manual loop tuning

- Effect of filtering on sensor outputs

- Commercial PID controllers

- Autotuning

- Ladder logic controllers

- Effect of sample time and cycle time

- Sensor calibration

- Sensor electrical characteristics

Key Industries

- Biopharmaceutical and Biotechnology

- Chemical

- Cosmetics & Personal Care

- Education & Academics

- Food & Beverage

- Oil & Gas

- Pharmaceutical

- Powders & Pigments / Coating

The Armfield Industrial Division designs and manufactures research & development systems, primarily for the food, beverage, dairy, edible oil and…

-

MALAYSIA

DKSH Technology Sdn. Bhd.

No. 108-B-01-08, Setia Spice Canopy, Jalan Tun Dr. Awang,

11900 Bayan Lepas, Penang

Malaysia

Download now

How to Disable Pop-Up Blockers for Smooth Downloads

Google Chrome (Version 110 and later):

- Click the three dots (menu) in the top-right corner and select Settings.

- Under Privacy and Security, click Site settings.

- Scroll down to Content and click Pop-ups and redirects.

- Toggle the switch to Allowed or add https://technology-products.dksh.com.my to the Allow list.

Mozilla Firefox (Version 90 and later):

- Click the three horizontal lines (menu) in the top-right corner and select Settings.

- Go to the Privacy & Security section.

- Scroll to Permissions and uncheck Block pop-up windows for https://technology-products.dksh.com.my.

Microsoft Edge (Version 110 and later):

- Click the three dots (menu) in the top-right corner and select Settings.

- Scroll down to Cookies and site permissions.

- Under Site permissions, click Pop-ups and redirects.

- Toggle the switch to Allow or add https://technology-products.dksh.com.my to the Allow list.

Safari (Version 14 and later):

- Open Safari and go to Preferences (from the top menu).

- Select the Websites tab.

- Under Pop-up Windows, select Allow for https://technology-products.dksh.com.my.