Armfield – Process Control Technology – PCT40 Multifunction Process Control Teaching System

This provides a cost-effective way of teaching a wide range of process control techniques, including temperature measurement and flow control. More sophisticated aspects of process control can be addressed by adding optional extras to the basic system.

The PCT40 is computer controlled with optional manual control available using the PCT43 Electronic Control Console.

Available Models

Key Features

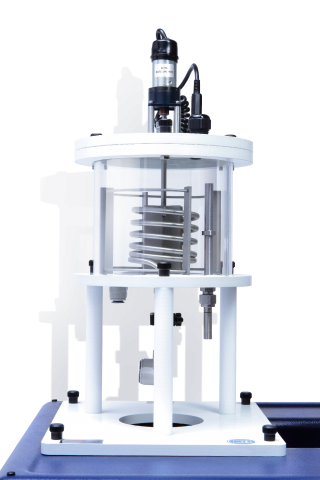

PCT40 Multifunction Process Control Teaching System

- A multi-function process control teaching system, capable of demonstrating level, flow, pressure and temperature control loops

- Bench mounted and includes a built-in USB computer interface

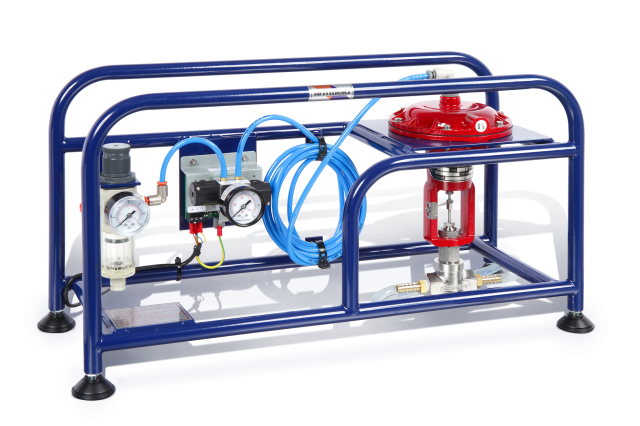

- Options include: reactor vessel with conductivity measurement, pH measurement, pneumatic control valve and electronic console

Includes the following process control demonstrations:

Process principles

- Calibration of sensors (via PC software)

- Inflow control

- Outflow control

- Direct heating

- Indirect heating

- Batch operation

- Continuous operation

- Effect of sensor lag (eg thermometer pocket)

- Effect of system time constant (eg volume change)

- Effect of dead time (eg holding tube)

- Effect of mixing/stirring (requires PCT41)

Measured variables

- Level – on/off switch (fixed hysteresis)

- Level – differential on/off switch (adjustable hysteresis)

- Level – proportional pressure sensor (slow system response)

- Flow – proportional turbine sensor

- Temperature – on/off switch (fixed hysteresis)

- Temperature – proportional thermocouple sensors

- Static pressure – proportional sensor (fast system response)

- Differential pressure – proportional pressure (fast system response)

- pH – proportional sensor (requires PCT41 and PCT42)

Controller types

- Manual control

- Effect of reverse/direct action

- On/off output with hysteresis

- Time proportioned output with adjustable P, I & D terms and cycle time

- PID proportional output with adjustable P, I & D terms

- Remote setpoint control (requires PCT41)

- Ratio, cascade and feedforward with feedback loops (requires PCT41)

Controlled variables

- On/off flow control via solenoid valves

- Time-proportioned flow control via solenoid valves

- Proportional flow control via pump speed

- Proportional flow control via electrical proportioning valve

- Proportional flow control via pneumatic proportioning valve (requires PCT44)

- On/off heater power control via solid state relay

- Time proportioned heater power control via solid state relay

- Proportional heater power control via solid state relay

Key Industries

- Biopharmaceutical and Biotechnology

- Chemical

- Cosmetics & Personal Care

- Education & Academics

- Food & Beverage

- Oil & Gas

- Pharmaceutical

- Powders & Pigments / Coating

More Products

The Armfield Industrial Division designs and manufactures research & development systems, primarily for the food, beverage, dairy, edible oil and…