AMADA – Linear DC Welding Controls – UB Series

Transistor direct current power supplies (also called “Linear DC”) produce much the same results as the high frequency inverter by using a high number of power transistors as the direct energy source. This technology provides clean, square wave forms with extremely fast rise time. Used primarily in constant voltage feedback control, transistor DC power supplies are effective in thin foils and fine wire welding applications and for extremely short welds.

The UB-4000A Linear DC welding control is ideal for applications which require exceptional control, fast rise times, and high quality throughput. UB-4000A requires only single phase input power and can output up to 4000 amps. Ultra-fast rise times permit short overall weld times, resulting in less part deformation and stronger welds. This is extremely important when welding heat sensitive parts such as battery cells or sensitive electronic devices.

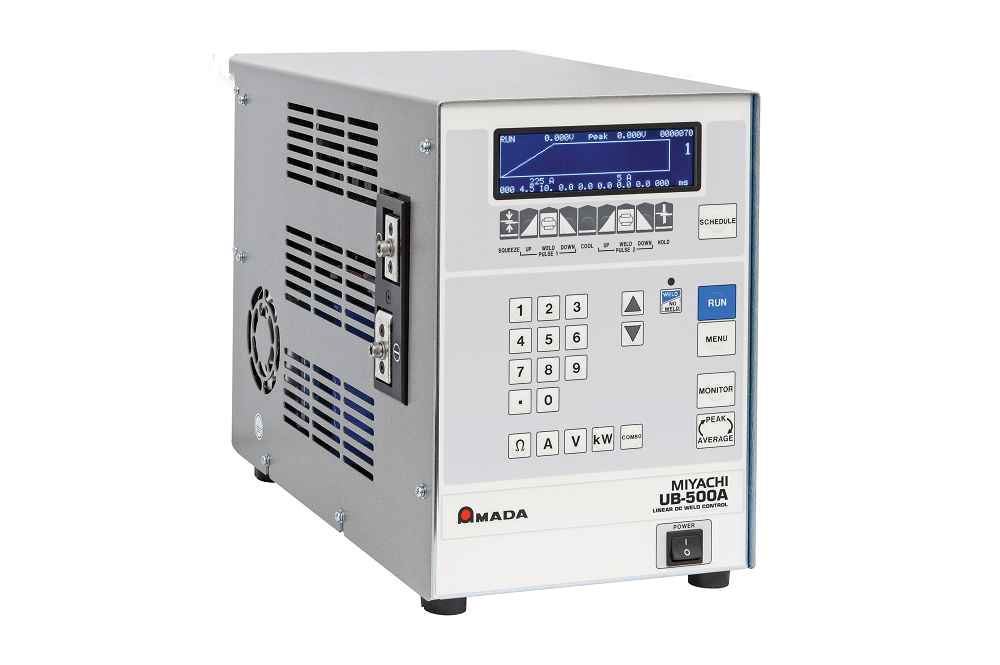

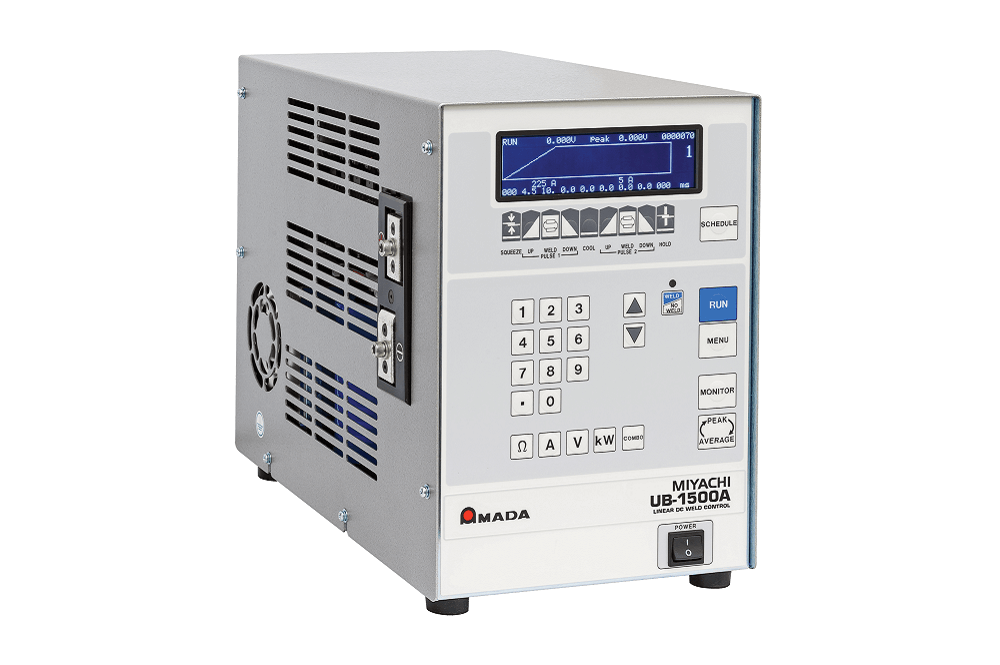

UB-500A (5-500 amps), and UB-1500A (15- 1500 amps) are Linear DC controls with feedback modes designed to adapt to part and process variables. These power supplies should be used for smaller applications where closed-loop feedback control and fast response times are required. Safety critical applications such as those found in the medical and automotive markets will benefit from UB-500A’s precision low energy control.

Available Models

Key Features

Linear DC Welding Controls – UB Series

- Advanced closed-loop analog control yields repeatable and stable programmable waveforms

- Extremely fast rise times permit shorter weld times, less part deformation, longer electrode life, and greater weld strength with more part ductility

- Built-in monitor with graphical screen shows visual trace of energy over time, aiding in weld parameter optimization

- Side mounted weld cables and compact unit size increase installation options

- Single phase power input and simple I/O allows for easy setup and versatility of use

Key Industries

- Aerospace

- Automotive

- Defense

- Electronics

- Machinery & Manufacturing

- Medical

- Semiconductor, Solar & Electronics

More Products

The AMADA Group is a world leader in the manufacture of machines for sheet metal processing. Established in 1946 by…