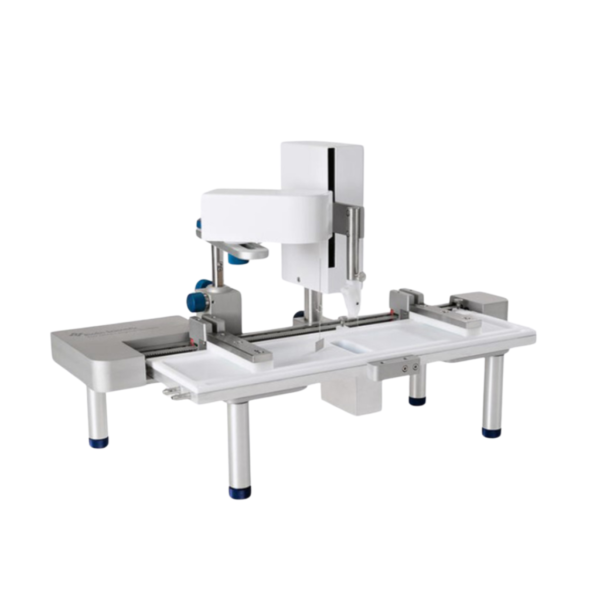

Binder – Drying and Heating Chambers – Series FED Avantgarde.Line – With forced convection and enhanced timer functions

BINDER heating chambers of the FED Avantgarde. Line series provide almost unlimited capacity and are particularly adaptable. With advanced timing functions and a controllable fan, temperature and convection conditions are easily controlled.

BINDER heating chambers of the FED Avantgarde. Line series provide almost unlimited capacity and are particularly adaptable. With advanced timing functions and a controllable fan, temperature and convection conditions are easily controlled.